My XPRIZE Experience

I joined Carbon Upcycling Technologies in the fall of 2018. I was looking for a relaxed job that would get me through my final semester of university. What I found instead was a career in an industry that strives to push the boundaries on technology with the hope of removing and utilizing enough carbon emissions that we can reduce the adverse impact of climate change.

My experience in the NRG COSIA Carbon XPRIZE offered an incredible professional opportunity that I will be forever grateful for. As a new grad, there is no better experience that I could have wished for. Great experience doesn’t always mean easy; in fact, it was extremely challenging. Particularly, from June to December 2020 when our team constructed a reactor that produces 20 tonnes of concrete additives in a batch. Prior to that, our largest reactor produced 2 tonnes of product.

I was named The Procurement Queen and spent hours procuring equipment from across the world with borders closing due to the pandemic. When our largest vessel arrived on site, my eyes welled up with happy tears. When the crane was undersized and couldn’t lift it, sad tears. One of many hurdles throughout the scale-up. Each more character-building than the last.

I coordinated with provincial and federal grant organizations to make sure we could complete our scale-up. Even though time was tight, I pitched at virtual startup competitions, then would run out the door to pick up more parts for the reactor. I knew the names of salespeople at over ten local parts suppliers and talked to them more than I talked to my friends and family.

When I say our team put blood, sweat, and tears into this scale-up, I mean it.

And it was worth it.

Today, I woke up and put on my shirt made by Expedition Air’s Artist in Residence, Annalee Levin. The design on the t-shirt is based on the Keeling Curve, a graph of research started in 1958 by Dr. Charles David Keeling who plotted changes in atmospheric carbon dioxide concentrations at the Mauna Loa Observatory in Hawaii. The shirt has been printed with ink made with Carbon Upcycling’s graphitic nanoplatelets.

Today, I washed my hands using soap made from carbon emissions. The bar of soap has been infused with potassium carbonate made from a technology developed by Expedition Air’s partner, CleanO2, as a means of reducing carbon emissions from the commercial heating industry. The revenue generated from the sale of these soap bars helps further their amazing research and development efforts.

Today, I watered my plant which I keep in a pot made by Vessel, a company whose slogan is Carbon Negative Plant Positive. One of the most poignant metaphors for the necessity of both industrial and natural climate solutions. The concrete is made with Carbon Upcycling’s concrete additive that reduces cement use by up to 20% and increases the strength of concrete by up to 40%. Most remarkably, this concrete additive has the ability to reduce the carbon footprint of concrete by up to 25% - a feat unmatched by any other carbontech company in the ready-mix concrete space.

In the carbontech space, we talk a lot about imagining a future where all the products around us are made from CO2.

At Carbon Upcycling Technologies, we are creating that future today. We launched Expedition Air, Carbon Upcycling’s consumer brand, to develop products that act as carbon sinks, storing more carbon emissions than they produce. Expedition Air also has a mission of facilitating collaborations with other carbontech companies, like that with CleanO2, because building a carbon economy is not something that can be accomplished by one company alone.

Of course, making or purchasing one of these consumer products is not going to save us from the climate crisis. Claiming so would be delusional and irresponsible. However, they do serve their purpose. In addition to the inspiration they lend for larger projects and partnerships, they also act as an indicator of the carbontech sector's development. All of the products I mentioned above have come into existence in just the one and a half years since we started working on consumer products.

Expedition Air has played a role in the start up of five companies that have materials made from carbon emissions as the premise of their businesses and we’re in discussion with half a dozen large brands to integrate Carbon Upcycling’s materials into their products. The stone or iron age economy built from the ground up, with an acheulean axe and a spear bartered one by one. We are nucleating the carbon economy the same way.

There is nothing more gratifying.

It's evident that the carbontech sector is rapidly advancing. Grand challenges, like the Carbon XPRIZE, facilitate the growth of technologies that propel this industry forward. They inspire great innovation and functional creativity. But this also calls for a twist on an old adage: with great influence comes great responsibility. I thoroughly believe that transparency, accountability, and validity need to be focal points for open innovation challenges. I am disappointed that this was not abundantly demonstrated in this competition and hope this can be rectified in future challenges.

However, I also know that a winner of a prize like this is only as valuable as the clients they earn after the spotlight is off of them. Another old adage: the proof is in the pudding.

We all need to demand better materials to be used in our products and I am immensely proud of the work our Carbon Upcycling team has done to make that a possibility for our clients.

There is no other team that I would have wanted to work with through this XPRIZE experience. This is just the beginning for our company and I can’t wait to see what this post-XPRIZE chapter has in store for us!

----------

A few moments from the Carbon XPRIZE:

Most of the Carbon Upcycling team in front of our largest reactor, Eta. This reactor was the main focus of our scale-up at the Alberta Carbon Conversion Technology Centre (ACCTC).

Peter in front of the Eta vessel on the day it arrived at the ACCTC.

Me holding a jar of Enhanced Talc Powder which is used as an additive in plastics.

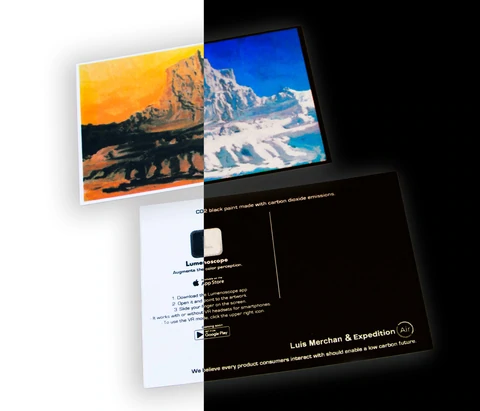

Some of the products created with our materials. I loved working with product developers and artists to create commercial products and demonstrate how captured and converted carbon emissions can be used in our everyday lives.

Chad, Apoorv, and Abraham in front of our second largest reactor, Zeta. This photo was taken at our lab in Bearspaw, AB where this reactor was used in the semi-final round of the Carbon XPRIZE. The reactor was then moved to the ACCTC for the final round.

Apoorv and Chad watch as the Zeta reactor runs smoothly for the first time on its new electric drivetrain at the ACCTC.

Natalie and I working at the ACCTC. We spent almost every day of our summer at site.

Ryan and Apoorv waiting to load a Burnco ready-mix truck with our concrete additive.

We spend a lot of time at concrete facilities. This is our team heading over to the quality control area of Burnco to have cylinders made for compressive strength testing.

The Carbon Upcycling team.